The first results are very promising

It’s a key milestone for Selfrag: Centro Uno, its innovative waste-to-value facility in Full-Reuenthal, Switzerland, has become operational and successfully entered the ramp-up phase. The team worked hard for this and the first results are very promising. Centro Uno has already proven that its capabilities will exceed the competition by far.

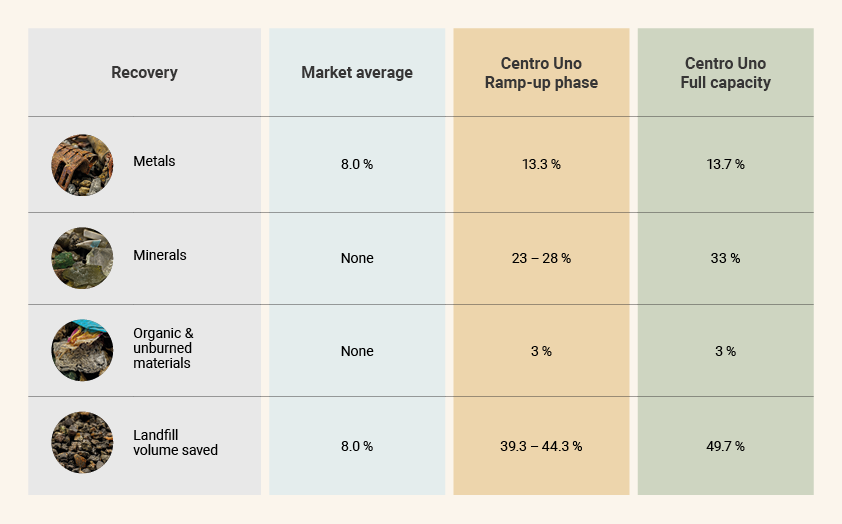

Unmatched recovery rates

Centro Uno uses patented technology to upcycle resources like metals and minerals from incinerator bottom ash (IBA). During the first few weeks of operation the plant delivered already industry-leading recovery rates. Overall, a total of 13,3% metals, 6,5% iron oxide, 23-28% minerals and 3% unburned materials have been recovered from IBA in the first weeks. These rates are approximately 3 times better than the ones obtained with conventional technologies.

Full capacity by July

The construction of Centro Uno started in January 2022 and was completed by the end of that year. With its operational capacity expected to reach 100% by July 13, Centro Uno will have a throughput of 35,000 tons of incinerator bottom ash annually. The slag is provided by the incinerators Renergia (Lucerne), Turgi (Aargau) and Buchs (Aargau). 50% of the material is set to be recovered in the process.

Game-changing technology

Centro Uno combines the SELFRAG 2.0 technology (selective fragmentation in the electrodynamic process) with density separation, washing and screening. The multi-step process includes a unique additional treatment of the mineral fraction using high-voltage pulses, which further reduces the content of heavy metal.

Reducing waste and CO2

The waste-to-value process reduces the amount of IBA ending up in landfills around Switzerland by 50%. But it also allows valuable materials such as scarce metals to re-enter the economy, thus contributing to a circular economy. Selfrag anticipates recovering approximately between 300 and 450 kg of CO2 per ton of slag treated. The company is going through the CO2 recovery certification process and intends to start issuing CO2 certificates in the course of this year.

With the continuous rise in waste production, waste recovery poses a significant global challenge. Selfrag’s strategic focus on waste-to-value has created a strong traction in Switzerland and we are currently involved in advancing new projects within the country.